Invention patent number: ZL 201510051291.1

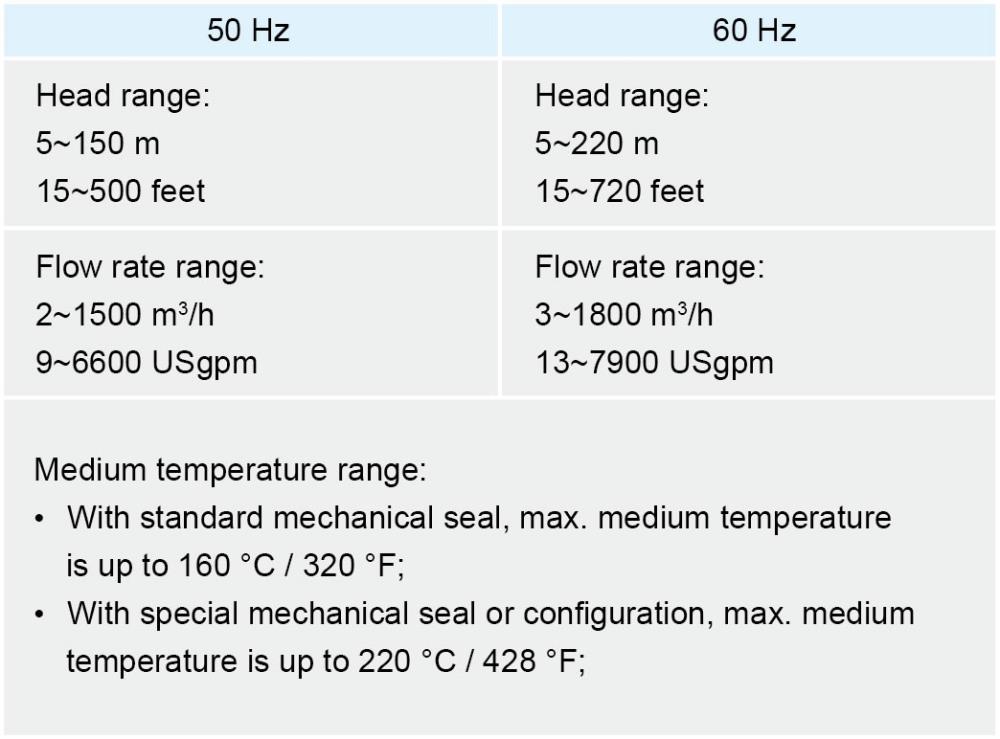

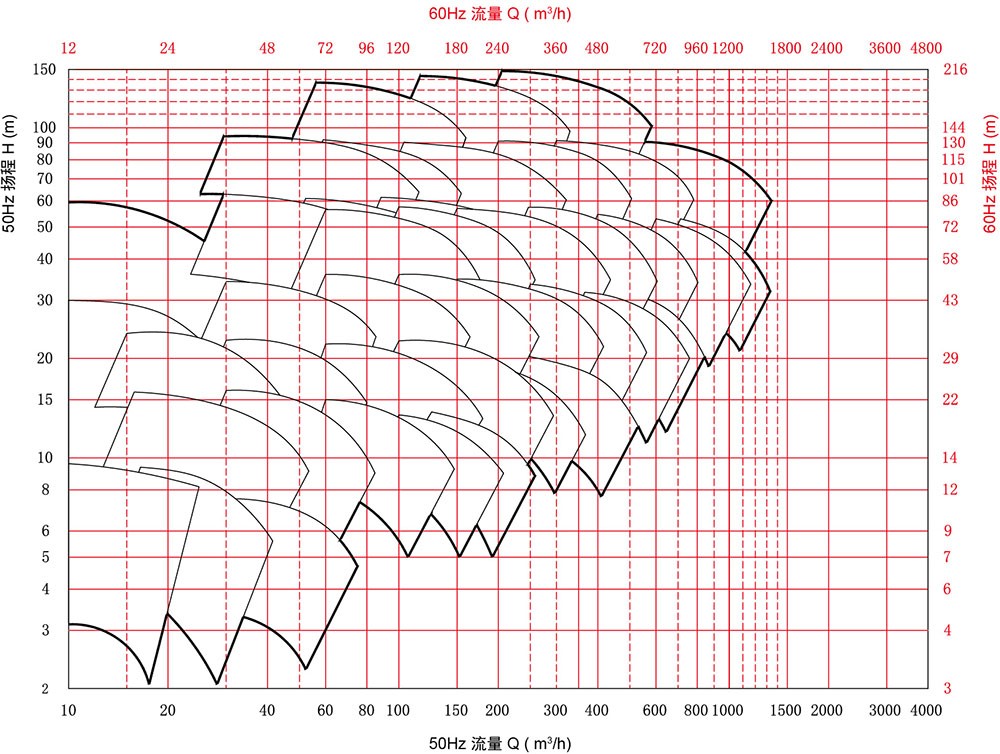

Operating data:

range of performance:

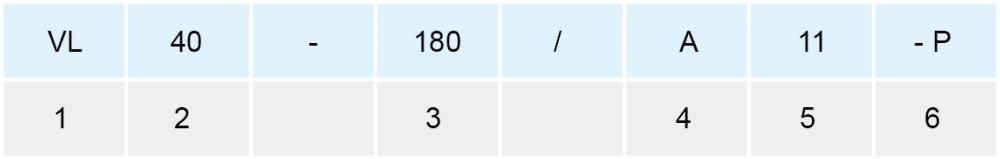

Pump Designation:

1: Pump Type

? VL:Vertical pipeline pump

? VLH:Horizontal end suction pump (parts are common with VL pump except for pump casing)

2: Discharge Nozzle Nominal Diameter (mm)

? Discharge nozzle dia. 40mm

Note: Equal Inlet & outlet dia. for impeller dia. ≤330mm as std. design

3: Impeller Nominal Diameter (mm)

? Impeller nominal dia. 180mm

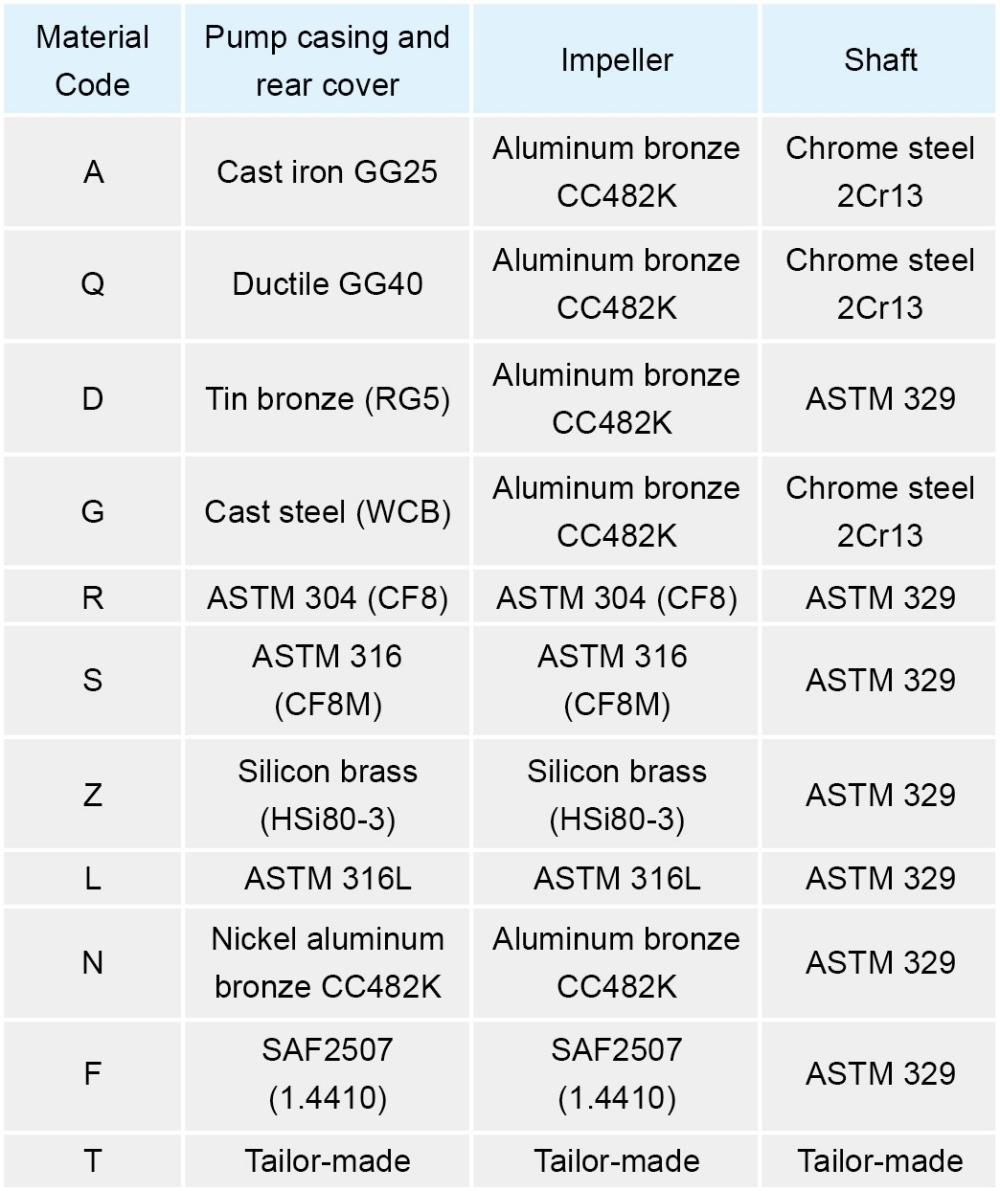

4: Material Code

5: Code of Pump Configuration

11: No bearing at pump end

12: Impeller rear slide bearing

13: Impeller rear anti-friction bearing

15: Impeller rear slide & anti-friction bearing

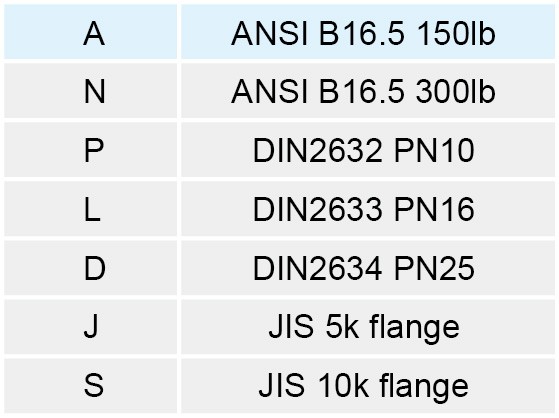

6: Code of Inlet & Outlet flange ratings

Note: Factory flange standard is P, which is to be supplied by default in case flange ratings are not mentioned in the order.

Core Technology Introduction(Typical application):

Suitable for a variety of marine applications, including seawater cooling systems, low temperature cooling systems, high temperature cooling systems, ballast water pumps and fire pumps.

1.Invention patent product. Patent number: ZL 201510051291.1;

2.High reliability:

?Shorter pump height to significantly reduce vibration and noise;

?Imported high-performance composite material for wear ring is optional to ensure the longest service life and lowest wear;

?Durability and service life are highly improved through optimized structure and precision processing;

3.Footprint and weight reduced:

?Re-optimization targeting marine service. Reducing the weight by up to 30% and reducing the product height by up to 20% compared to well-known international marine pumps;

4.High efficiency:

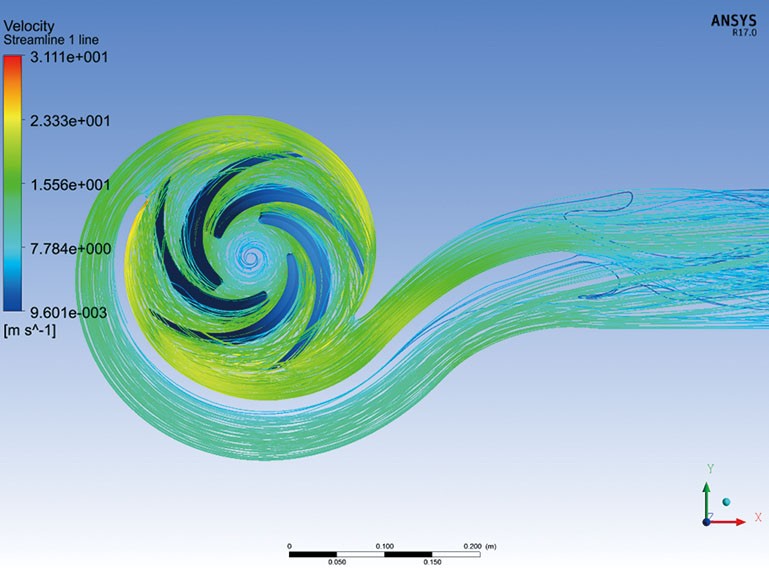

?Energy-saving products by using optimized hydraulic model (high-order equation G2-A surface design method) to improve efficiency and cavitation performance; in conformance with MEI0.7 European energy-saving standards; efficiency is about 5% higher than well-known international marine pumps;

5.Easy to maintain:

?Modular design; the main components of different structures (back cover, bracket, shaft, etc.) are interchangeable. Altering or upgrading the configuration only requires to replace the relevant parts module while keeping installation dimensions unchanged;

?Mechanical seal and impeller can be replaced without disassembling the pump volute, motor or bracket. The maintenance time can be saved by about 50% compared with well-known international marine pumps;

6.Mechanical seal is standard configuration; double mechanical seal or packing seal is optional;

7.Pump can be upgraded to common self-priming pump or strong self-priming pump for cavitation-prone installations;

8.Double volute design greatly reduces the radial force of the pump and the weight of the pump casing;

PUTRONS VL Illustration of spare parts replacement: